In industry a very common term that is used frequently is " Safety first". Grounding is first step of safety. Being laid under ground it plays a very important role for ensuring human safety as well as equipment safety.

Let's see how.

1. Non current carrying electrical point (neutral) or

2. Metallic enclosure of any equipment

to earth.

The first one is called "Neutral Grounding" and the second one is called "Body Earthing or grounding"

We have known what is grounding, now comes the most important question

"Why we need grounding?"!!!!!

Let's see-

1. Purpose of Neutral Earthing or grounding: Neutral earthing is done for mainly two reasons.

a) To keep the neutral point of any star connected 3 phase system at earth potential.

b) To provide a complete path for current during earth fault so that it can be detected.

|

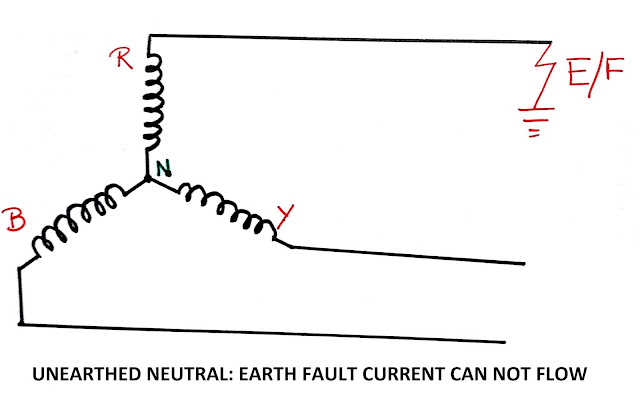

| FIG 1:- GROUNDING_E/F WITH UNEARTHED NEUTRAL/https://electricaltechnologyrishi.blogspot.com |

The image shows a neutral point with no earth connection i.e. "Unearthed Neutral"

We can also see that if any earth fault occurs at any phase the fault current shall have no path to go, causing huge potential rise and an undetected hanged earth fault.

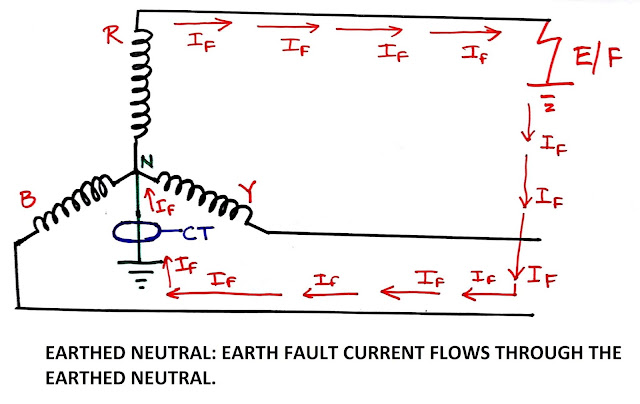

Now let us see the previous system with neutral connected to earth. Here it can be seen clearly that Earth fault current has a complete path to return through the neutral point via earth.

This current cam easily be detected by placing a current transformer at the neutral. There are many other methods of detecting earth fault also.

Please refer to our article CT connection to sense earth fault/Earth Faults Detection Philosophy for these details.

Please refer to our article CT connection to sense earth fault/Earth Faults Detection Philosophy for these details.

So from the above observation it seems to be obvious that ungrounded neutral should not be used any where.

It is true that almost in every case neutral point of any star connected system may be a generator or transformer is earthed. But where delivering power is more important than detecting earth fault, for those cases the neutral remains open. Let me explain.

In power plant there are emergency diesel generators which deliver power when the power plant fails for safe shut down of the power plant. Basically in a power plant the turbine and the main generator are the most expensive equipment, so during any disturbance it is necessary to safely shut down those two equipment. As during complete blackout of a power plant the emergency dg feeds power, then it is more important that the DG must deliver power without any interruption. That's why neutral of the DGs are kept open so that it doesn't trip for earth leakage or earth fault.

So, we can say neutral earthing is done for equipment safety i.e. to detect an earth fault and isolate it.

Now we shall see the second type of grounding i.e. body grounding or body earthing.

2. Purpose of Body Earthing or grounding: We have already mentioned that conneting the metallic enclosure of an equipment to ground is called Body Earthing. It is done for human safety, whis is the most essential criteria of industrial practice.

Every Electrical equipment has winding inside it which is charged with rated voltage and carries current as per its rating. The windings are insulated for its rated voltage, hence current is confined only in the cross section of the conductor. But there are two situations when this consideration may not remain valid.

CASE 1- What will happen if insulation of the outer most winding get damaged?

In that case voltage of the winding will try to break down the airgap with the enclosure or the insulating material.

If the insulation is damaged enough and the voltage is also high enough then it will become capable to break down the airgap insulation between the winding and enclosure.

If the enclosure is not earthed, and at this condition an operator touches the enclosure then the winding will cause a leakage current through the airgap, operator's body to the ground. Thus the person will experience electrical shock, due to leakage current.

|

| FIG 3:- GROUNDING_LEAKAGE DUE TO INSULATION DAMAGED_METALLIC ENCLOSURE NOT EARTHED/https://electricaltechnologyrishi.blogspot.com |

But if the enclosure was earthed then?

Then this leakage current would flow through the earthed conductor to ground. If the leakage current is high enough or the earth fault detection system is sensitive enough (See article- CT connection to sense earth fault/Earth Faults Detection Philosophy, Restricted Earth Fault Protection Philosophy) then it shall be treated as earth fault and by earth fault relay the faulty machine shall be isolated.

|

| FIG 4:- GROUNDING_LEAKAGE DUE TO INSULATION DAMAGED_METALLIC ENCLOSURE EARTHED/https://electricaltechnologyrishi.blogspot.com |

CASE 2: The second possibility is that if the conductor inside the equipment got broken and had touched the enclosure then the voltage will appear to the enclosure. If the enclosure is earthed then it will be treated as earth fault causing the earth fault relay to operate and isolate the fault, but if the enclosure is not earthed then accidental contact with that equipment an operator will experience fatal shock.

Conditions are similar with the picture shown above, only in the shown picture current is flowing due to insulation damage, where as here current will flow as a conductor.

So we can hereby conclude that all metallic enclosure of Electrical equipment shall be connected to earth. Basically in industry all metallic structure, enclosure, are suitably earthed.

GENERAL METHODS OF GROUNDING:

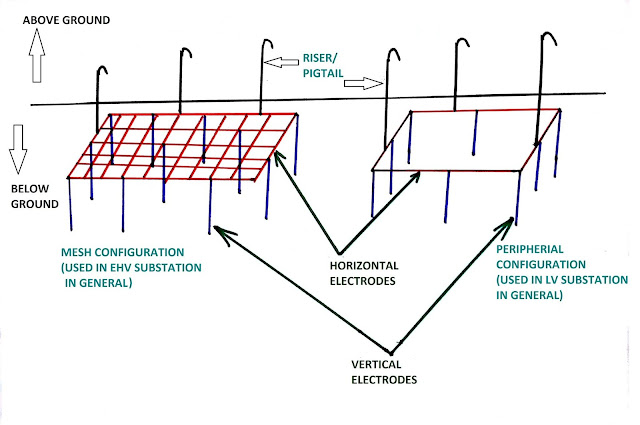

Ground mat/ grid are buried under ground. Grounding systems are comprises of horizontal and vertical conductors.

Horizontal conductors cover the area that to be grounded. And vertical conductors basically kept to release the earth fault current to deeper ground. Many configurations of horizontal conductors are used like simple peripherial configuration, mesh configuration etc. depending on the voltage level. Detailed discussion about the grounding conductor configuration selection is beyond scope of this article, we shall give details in the upcoming articles.

|

| FIG 5:- GROUNDING_LEAKAGE DUE TO INSULATION DAMAGED_METALLIC ENCLOSURE EARTHED/https://electricaltechnologyrishi.blogspot.com |

For neutral point earthing at least two vertical electrodes are buried. These two electrodes are connected with the main grounding grid. And neutral point is connected with this electrodes by G.S flat or cable as applicable.

From the main ground grid risers are kept. Equipment are connected to the risers as reuired.

This is the very basic method of of grounding. But there are many other factors for a safe grounding design which shall be discussed in the upcoming articles.

Hope you have enjoyed this article. Please share your opinion in the comment box. And for all of our other posts please visit the page "Site Map"

Thank you.......

Thank you so much.. your support is making me feel that my efforts have not gone in vain..

ReplyDeleteKeep sharing..

Existing without the answers to the difficulties you’ve sorted out through this guide is a critical case, as well as the kind which could have badly affected my entire career if I had not discovered your website.

ReplyDeletenebosh course in chennai

Very Useful information. Thanks for sharing this article

ReplyDeleteRead More Article

This blog site is actually helpful to provide upgraded affairs over web which is actually appraisable. Indoor Garden Supplies

ReplyDeleteIcon process Controls offer wireless sentinel series Telemetry Level Sensor system. Local visual display indication entirely corrosion resistant PVDF transducer push button programming narrow beam technology small deadband (maximizes filling capacity of the tank) cost effective general purpose. By using our Telemetry Tank Level Sensor make your industry low cost effective and minimize the waste.

ReplyDeletereally such a good article about Purpose of Neutral Earthing or grounding and WHAT IS GROUNDING keep sharing more information related to this

ReplyDeleteClick here http://intertech.com.co/

I found that site very usefull and this survey is very cirious, I ' ve never seen a blog that demand a survey for this actions, very curious... Click here

ReplyDeleteThis is my first time i visit here. I found so many interesting stuff in your blog especially its discussion. From the tons of comments on your articles, I guess I am not the only one having all the enjoyment here keep up the good work pinoy1tv

ReplyDeleteExcellent article. Very interesting to read. I really love to read such a nice article. Thanks! keep rocking. thermal imaging company

ReplyDeleteThere are also two glazing variations made to construct this type of glass. First, is the insulated or double glazing method. This consists of several glazing layers that are put together. A dead space occupies the squeezed part of the two layers to ensure that proper insulation and noise reduction is achieved. gözlüğü

ReplyDeleteYou should add Floating neutral terminology as well along with pipe earthing and plate earthing details.

ReplyDeleteThe post is written in a very systematic way. It is very easy to grasp contents,

ReplyDeletePenjelasannya mudah dimengerti dan cukup jelas, menambah pengetahuan kelistrikan, untuk pengetahuan terkait kelistrikan lainnya dapat kunjungi voltechno.net

ReplyDeleteThanks

ac

ReplyDeleteLooking for- https://coraductcleaning.com Best Duct Cleaning in Toronto, must visit Cora.

ReplyDelete